Ring Frame

Fluted Rollers

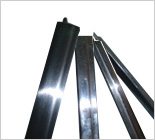

Since FOUR DECADES, we manufacture bottom rollers with unrivaled standards of quality and concentricity by the introduction of most sophisticated manufacturing techniques. The optimal groove angles and shape provide along with special surface finish provide smooth running and better fiber control over the rollers. The rollers are made out of EN-9 Grade Steel, Cold Rolled Helical fluted Knurled rollers which provides more number of nipping points for better control of fiber and better cot life, High frequency induction hardened to withstand high pressure of Modern Top arm, precisely ground flutes to give better yarn quality and free from peak problems. The two matting faces of the rollers are ground in perpendicular to the male and female portions. Optimum clearance maintained between the bore and pilot. These aspects results in Eccentric free rotation for long years. Our rollers suits for 100% Cotton, Blends of Cotton and man made fiber or 100% man made fiber.We provide both Anadised (blackening rollers) rollers, which prevents rust formation and hard chrome platted rollers, which has high wear resistance and anti corrosion properties.

We manufacture fluted rollers for various processes as mentioned below from 20mm diameter to 62.5mm diameter.

Roller Stands

Nathan Make roller stands for

-

-

Speed frames (Simplex Frame)

-

Doubling roller stand

We manufacture Cast Iron Roller Stand which are made out of high grade induction melt Cast Iron, Most precisely machined, perfect in all aspect suitable for Ring Frame and Speed Frame and Doubling Machine as per your requirement of various center height and various drafting angles like 45°and 60° for Ring Frame and 15/ 10° for Speed Frame. We provide both Needle Bearing type Roller Stand and Bush Bearing type Roller Stand

We manufacture Cast Iron Roller Stand which are made out of high grade induction melt Cast Iron, Most precisely machined, perfect in all aspect suitable for Ring Frame and Speed Frame and Doubling Machine as per your requirement of various center height and various drafting angles like 45°and 60° for Ring Frame and 15/ 10° for Speed Frame. We provide both Needle Bearing type Roller Stand and Bush Bearing type Roller Stand

-

We provide Roller Stand with and without slides for Middle and Back Lines.

-

We provide slides separately.

Bottom Apron Tension Devices

-

Double Row Ball Bearing type:

Double Row Ball Bearing type tension device gives you friction free smooth rotation of the apron. Higher circumference of the rollers prevent sharp bending of the bottom aprons which results in long life of the bottom Aprons.

-

Aluminum Fork Type:

WE provide Pressure die cast Aluminum fork for both Ring frame and speed frames, this is the most economical and effective tension devices when compared with dead weight type rollers.

-

Dead Weight type:

This the older version of tension Devises used earlier.

Nose bars

High performance step Type Nose Bar for short, medium and long cradle we can supply Nose bar( Bridge bar) according to your mills requirement which results in significant improvement of yarn quality, and also improvement in U%.

High performance step Type Nose Bar for short, medium and long cradle we can supply Nose bar( Bridge bar) according to your mills requirement which results in significant improvement of yarn quality, and also improvement in U%.