It is a unique special process to remove carbon deposits associated with the manufacturing process.

Stationary Flat Tops

XL-Type-A

|

|

||||||||||

Sanmit products fit for all 40" Cards

| S.No. | Sanmit Model |

| 1. | SM.3H (SFD - Front & SFL - Back),SM.3HA (SFL - Back Side ) & SM.3H333 (under Licker - in) |

| 2. | D-K 760 , D-K 760 - old, D-K 780, D-K 800 & D-K 803 (Existing 3 Flat C-System) |

| 3. | D-K 803 & D-K 903 (Under Licker - in Segments) |

| 4. | C - System for all cards (Screw type) |

Sanmit products fit for all 60" Cards

| S.No. | Sanmit Model |

| 1. | INGOLSTADT - SSKU 12 |

XL-Type-B

|

|

||||||||||

Sanmit products fit for all 40" Cards

| S.No. | Sanmit Model |

| 1. | D-K 715, D-K 740, D-K 760 (Aluminium Base), D-K 800 (Twin Flat), D-K 903, T-C 03 / 05 / 06 / 07-S / 08 / 11 / 15 & All Twin Flat System Carding Machines |

| 2. | MK - 4, MK - 5, MK - 5A, MK - 5B, MK - 5C, MK - 5D & MK - 6 & MK - 7 |

| 3. | C.1/2, C.1/2A, C.1/3, T.C.360, I.C.C T.C 450, C 4, C 10, C 50 & c 51 |

| 4. | HOWA - CMSK - 3, CMSK - 4 & CMSK - 5, CM300 & CMS80 |

| 5. | TOYODA & TOYODA MEIKIN All model |

| 6. | JFA 186, JFA 201, JFA 203, JFA 203A, JFA 203B, JFA 212, JFA 225, JFA 226, JFA 227, JFA 228, JFA 231C, JWF 1204 & all other CHINESE card |

| 7. | I.C.C. - C - System & Under Licker - in Segments for all Carding Machines |

| 8. | JAPANESE All Carding machines |

| 9. | C 40, C 41, CX 300, CX 400, CX 501 & CX 601 (front, Back & Under Licker-in) |

Sanmit products fit for all 50" Cards

| S.No. | Sanmit Model |

| 1. | T-C 11 / 15 |

Sanmit products fit for all 60" Cards

| S.No. | Sanmit Model |

| 1. | C60, C61 & C70 |

| 2. | C701 |

| 3. | SM.6H36 |

XL-Type-C

|

|

|||||

Sanmit Products

Under Lickerin Segments - Suitable for 40" cards

| S.No. | Sanmit Model |

| 1. | D-K 715, D-K 740, D-K 760, D-K 780 & D-K 800 |

| 2. | C.10, C.50 & C.51 |

| 3. | C.1/2, C.1/2a, C.1/3, SM.H, SM.3H, SM.3HA, SM.3HA-V3, SM.3HA-V4, SM.3H61, SM.3H63, T-C 360, T-C 450 & other 40" cards |

| 4. | JFA 186, JFA 201, JFA 203, JFA 203A, JFA 203B, JFA 212, JFA 225, JFA 226, JFA 227, JFA 228, JFA 231C, JWF 1203, JWF 1204 & other CHINESE cards |

| 5. | BLOW ROOM CVT - 3 & CVT - 4 (FD 60) |

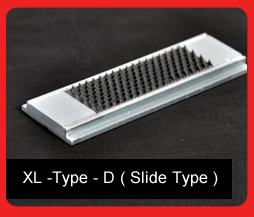

XL-Type-D

|

|

||||

Sanmit Products for UNIFLEX Carding Segment

|

|||||

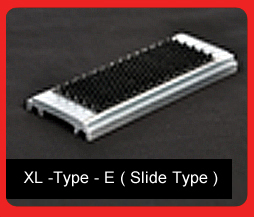

XL-Type-E

|

|

||||

Sanmit Products

|

|||||

| S.No. | Sanmit Model |

| 1. | C 4 |

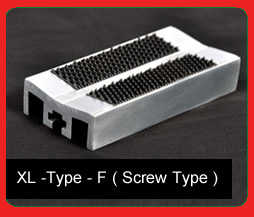

XL-Type-F

|

|

||||

Sanmit Products

|

|||||

| S.No. | Sanmit Model |

| 1. | TC 03 / 05 / 5-3 / 06 / 07-S /08 /10 |

XL-Type-G

|

|

Sanmit Products fit for all 40" cards

| S.No. | Sanmit Model |

| 1. | MK-4 & MK-5 (Clip type C-System) |

| 2. | D-K 715, D-K 740 & D-K 760 (Cast Iron & AI. C - System) |

| 3. | JFA 186, JFA 201A, JFA 201B, JFA 231A, JFA 221D, C - System & Chinese Cards |

| 4. | HOWA-CMSK 3 & CMS 80 / TOYODA-CK 7 & TOYODA MEIKIN |

| 5. | Clip Type C- System for all Carding Machines |

XL-Type-H

|

|

Sanmit products fit for all 40" Cards

| S.No. | Sanmit Model |

| 1. | SM.3HA (Front - SFD) |

| 2. | SM.3HA - V3 (Front & Back), SM.3H33 (Front & Back) SM.3H61 & SM.3H63 (Front & Back) |

| 3. | C.1/2, C.1/2a, C.1/3 & SM.H (Front & Back) C-System and C-Factors for all Card |

| 4. | C-System for SFL & SFD FOR C.1/3, SM.3HA, SM.3HA - V3/V4, SM.3H3 (Front Conversion (SFD)) |

XL-Type-L

|

|

|||

| ECC underlickerin segments for HOWA Cards. | ||||

Salient Features:

|

C-System

SFL (Above Lickerin) - Back Side

Stationary flats are designed from coarser PPSI - bottom to Finer PPSI - top gives excellent pre opening of heavier fibre tufts. Mote knife and suction device removes trash particles and even distribution of fibres.

Salient Features

-

Machine originality will be maintained during modification.

-

Stationary Flat Tops are designed from coarser PPSI - bottom to Finer PPSI - top gives excellent pre opening of heavier fibre tufts. Mote knife and suction device removes trash particles and even distribution of fibres.

-

Imported high quality Stationary Flat Tops wires ensures yarn sliver quality and consistency in life.

-

It gives good parallelization of fibres and results reduces the carding strain and increases the life of cylinder wire and revolving flats.

-

Individual adjustment of Stationary Flat Tops and mote knife makes accurate gauging which helps carding quality and production at higher speeds.

-

Smooth finish suction device helps to remove micro dusts, short fibres and motes and help to maintain clean suction in the machine.

-

Aluminium flats are made out of alloy grade smooth finish extrusion materials which gives flat stability.

Suitability: C1/2, C1/2a, C1/3, SMH, SM3H, SM3HA & SM3HA-V3 / SM3HA - V4.

SFD (Above Doffer) - Front Side

Finer PPSI stationary flats, mote knife and smooth finish suction device helps to improve classimate results.

Salient Features

-

Machine originality will be maintained during modification

-

Sturdy Al. base beam with individual adjustment of stationary flats and mote knife makes accurate gauging which helps carding quality and production at higher speeds.

-

Web transfer from cylinder to doffer is very easy when added more number of finer PPSI Stationary Flat Tops in front side.

-

Finer PPSI Stationary Flat Tops, mote knife and smooth finish suction device helps to improve classimate results.

-

Individual adjustment of Stationary Flat Tops and mote knife makes accurate gauging which helps carding quality and production at higher speeds.

-

Smooth finish suction device helps to remove micro dusts, short fibres and motes and help to maintain clean suction in the machine.

-

Aluminium flats are made out of alloy grade smooth finish extrusion materials which gives flat stability.

-

No gap between each flat prevents dust liberation. No need for sticking forms between each flat.

-

Individual gauging Stationary Flat Tops is easy replaceable

Suitability: C1/2, C1/2a, C1/3, SMH, SM3H, SM3HA & SM3HA-V3 / SM3HA - V4.

New Development C-System Kit

5 Flats + 1 Mote knife conversion suitable for : SM.3HA V4, SM.3HA V3, SM.3HA, SM.3H

Upgrade your Carding Machine to acheive

-

IPI Reduction Minimum - 10% to Maximum 20%.

-

Clasimate Improvement ( A1 & A2 fault) upto 20% from Existing Quality.

Results will achieved on Identical Testing Conditions on Same Carding Machine ( Before & After )

Advantages :

-

Stationary Flat Tops Design and Wire geometry (wire profile) – Same as European (Latest design).

-

Materials – Imported from Europe in the form of 50kg roll like Cylinderwire (Teeth Cutting & Hardening done in Europe like Cylinder wire).

-

Design of this C-System is Wedge sharper and the possibilities for bending and twisting is negligible.

-

Dust free C-System working atmosphere is maintained.

-

Smooth Aluminium Suction device maintains clean suction.

-

8 point gauging system maintains Zero gauge setting (Prefect gauge will be achieved during installation).

-

Better aesthetics gives an original look.

-

Minimum quality will be achieved 10% to 20% from existing results on identical testing conditions.

-

More no of stationary flat tops will lead to better parallelization and removes fibre hooks – results in improved winding and spinning efficiency.

-

Will support to improve Classimate results (A1 & A2 fault level).

Suitability: For Cotton.

Pre Opening Combing Segments - (Economic)

Salient Features

-

Construction of assembly is replaceable slide(strip) type.

-

Economic replacement for conventional araldite and punched sheets combing segments..

-

Sharp points gives better pre-openings that results in minimum loss of good fibres

-

Aluminium combing bars are made out of alloy grade smooth finish extrusion materials which gives flat stability.

-

Machine original mote knives can be fixed without any alterations in assembly.

-

Easy replaceable and cost economic during replacement time.

Suitability: D-K715, D-K740, MK4 & MK5.

Pre Opening Combing Segments - (Individual Gauging)

Salient Features

-

Construction of assembly is individual gauge setting and replaceable slide (strip) type.

-

Individual gauge setting ensures accurate gauging which results in better opening of fibre tuffts in lickerin zone.

-

Sharp points gives better pre-opening that results in minimum loss of good fibres.

-

High quality hardened mote knives help to remove smaller and heavier trash particles results good reduction of neps in lickerin zone.

-

Easy replaceable and cost economic during replacement time.

-

Made out of high grade individual flat aluminium bars which gives more stability to ensure accurate gauging.

Suitability: D-K715, D-K740, MK4 & MK5

RSK Pin Beater Segments

-

Designed with two pin beater segments and two perforated Control sheets to ensure removal of heavy trash and impurities with the help of gentle fibre tufts opening.

-

Easy replaceable with two slotted perforated control sheets which reduces fibre rupture and good fibre loss.

-

Ensures cleanng efficiency upto 20%.

-

Ensures consistent fibre tuft quality in blow room machines.

Suitability: Open end & Fine spinning BLOWROOOM & CARDING MACHINES

Sanmit C-System Recommendation & Scope of supply

| Card Model | Above Doffer (SFD) | Above Lincker-in (SFL) | Pre Opening Combing Segments (Under Lickerin) |

Process |

|---|---|---|---|---|

| D-K715 & D-K740 | 5 F + 1 K + Suction | 7 F + 1 K + Suction | 4 Segments + 2 K | Cotton |

| 9 F | 11 F | 4 Segments + 2 K | Synthetic | |

| D-K760 D-K780, D-K800 D-K803 (Single Licker in) |

6 F + 1 K + Suction | 8 F + 1 K + Suction | - | Cotton / Synthetic |

| D-K803 & D-K903 (3 Licker-in - Twin Flat) |

6 F + 1 K + Suction | 6 F + 1 K + Suction | - | Cotton / Synthetic |

| D-K706 (Cast Iron base C-System) |

6 F + 1 K + Suction | 7 F + 1 K + Suction | - | Cotton / Synthetic |

| MK - 3 | 6 F + 1 K + Suction | 12 F + 1 K + Suction | - | Cotton / Synthetic |

| MK - 4 & MK - 5 | 6 F + 1 K + Suction | 8 F + 1 K + Suction | 4 Segments + 2 K | Cotton / Synthetic |

| C4 & C10 | 4 F + 1 K + Suction | 8 F + 1 K + Suction | - | Cotton / Synthetic |

| C50 & C51 | 4 F + 1 K + Suction | 7 F + 1 K + Suction | 4 Segments + 2 K | Cotton / Synthetic |

| SM.3H, SM.3HA SM.3HA - V3 & SM.3HA - V4 |

5 F + 1 K + Suction | - | Economic Model Combing Segment Full Set |

Cotton / Synthetic |

| C .1/2, C.1/2a, C 1/3, (Economic model) |

6 F + 1 K + Suction | 3 F | Economic Model Combing Segment Full Set |

Cotton / Synthetic |

| Chinese - FA201 | 7 F + 1 K + Suction | 11 F + 1 K + Suction | - | Cotton |

| Chinese - FA 186 | 5 F | 12 F | - | Synthetic |

| HOWA - CMS80 HOWA-CMSK3 / Toyoda-Meikin |

6 F | 12 F | - | Synthetic |

| Toyoda - Meikin | 6 F + 1 K + Suction | - | - | Cotton |

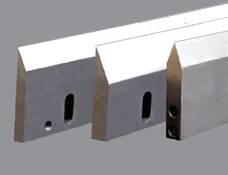

Steel Mote Knives

Salient Features

-

Mote Knives made out of high grade alloys steel material En8 / En31.

-

Smooth finish grinding with Hard Chrome Piating ensures smooth fibre transfer.

-

Hardened to 58 to 60 HRC will ensures long life.

-

Precision dimensional accuracy as per OEM ensures perfect filament to reduce machine downtime.

-

Long life with competitive price.

-

Special knives can be manufactured as per customer requirement for all machines.

| BLOW ROOM MOTE KNIFE | ||||

| S.No. | Blowroom Model | Type | Drawing No | |

| 1. | CVT 3 & CVT 4 | 1st Roller Knife | SANMIT - BR - 1001-626 | |

| CVT 3 & CVT 4 | 2st Roller Knife | SANMIT - BR - 1002-627 | ||

| CVT 3 & CVT 4 | 3rd Roller Knife | SANMIT - BR - 1003-626 | ||

| 2. | KIRSCHNER BEATER | 1st Roller Knife | SANMIT - BR - 1004-583 | |

| 3. | ERM 5 / 5 | 1st Roller Knife | SANMIT - BR - 1005-622 | |

| 4. | ERM 5 / 6 | 1st Roller Knife | SANMIT - BR - 1006-623 | |

| ORIGINAL MACHINE | ||||

| SM.3H, SM.3HA / SM.3HA-V3 & SM.3HA-V4 | ||||

| S.No. | Description | Drawing No | ||

| A | FRONT C-SYSTEM M/C Original for SM.3H | SANMIT - D - 4001-588 | ||

| B | BACK C-SYSTEM M/C Original for SM.3H | SANMIT - D - 4002-589 | ||

| C | FRONT-TOP KNIFE | SANMIT - D - 4003-364 | ||

| D | BACK-TOP KNIFE | SANMIT - D - 4004-364 | ||

| E | BACK-BOTTOM KNIFE | SANMIT - D - 4005-364 | ||

| F | UNDER LICKER-IN 1st Knife | SANMIT - D - 4006-274 (12mm) | ||

| G | UNDER LICKER-IN 1st Knife | SANMIT - D - 4007-418 (15mm) | ||

| H | UNDER LICKER-IN 1st Knife | SANMIT - D - 4008-687 (5mm) | ||

| I | UNDER LICKER-IN 2nd Knife | SANMIT - D - 4009-273 (8mm) | ||

| J | UNDER LICKER-IN for SM.3H | SANMIT - D - 4010-590 (5mm) | ||

| K | UNDER LICKER-IN for SM.3H | SANMIT - D - 4011-591 (8mm) | ||

| SM.3H33, SM.3H61 & SM.3H63 | ||||

| A | FRONT-TOP KNIFE | SANMIT - D - 4012-582 | ||

| B | FRONT-BOTTOM KNIFE | SANMIT - D - 4013-582 | ||

| C | BACK-TOP KNIFE | SANMIT - D - 4014-364 | ||

| D | BACK-BOTTOM KNIFE | SANMIT - D - 4015-364 | ||

| E | UNDER LICKER-IN 1st Knife | SANMIT - D - 4016-801 (8.5mm) | ||

| F | UNDER LICKER-IN 2nd Knife | SANMIT - D - 4017-803 (5mm) | ||

| C.1/2 & C.1/3 | ||||

| A | FRONT-TOP KNIFE | SANMIT - D - 4018-364 | ||

| B | BACK-TOP KNIFE | SANMIT - D - 4019-364 | ||

| C | UNDER LICKER-IN 1st Knife | SANMIT - D - 4020-274 (12mm) | ||

| D | UNDER LICKER-IN 1st Knife | SANMIT - D - 4021-418 (15mm) | ||

| E | UNDER LICKER-IN 1st Knife | SANMIT - D - 4022-687 (5mm) | ||

| F | UNDER LICKER-IN 2nd Knife | SANMIT - D - 4023-273 (8mm) | ||

| SM.H | ||||

| A | FRONT-TOP KNIFE | SANMIT - D - 4024-580 | ||

| B | UNDER LICKER-IN | SANMIT - D - 4025-451 | ||

| D-K740 | ||||

| A | BACK-TOP KNIFE | SANMIT - D - 4026-492 | ||

| B | LCC C-FACTOR | SANMIT - D - 4027-826 | ||

| C | FEEDER ROLLER KNIFE (BEFORE UNDER COMBING SEGMENT) | SANMIT - D - 4028-577 (20mm) | ||

| D-K760 (CAST IRON BASE) | ||||

| A | BACK-TOP KNIFE | SANMIT - D - 4029-828 | ||

| B | FRONT-TOP KNIFE | SANMIT - D - 4030-829 | ||

| C | FRONT-BOTTOM KNIFE | SANMIT - D - 4031-830 | ||

| D-K760, D-K780 (3 Flat C-System) D-K800 (Twin flat) | ||||

| A | FRONT-TOP KNIFE | SANMIT - D - 4032-495 | ||

| B | FRONT-BOTTOM KNIFE | SANMIT - D - 4033-495 | ||

| C | BACK-TOP KNIFE | SANMIT - D - 4034-494 | ||

| D | I.C.C NEW C-SYSTEM SUCTION KNIFE | SANMIT - D - 4035-674 | ||

| E | L.C.C. C-FACTOR | SANMIT - D - 4036-826 | ||

| F | UNDER LICKER-IN 1st Knife | SANMIT - D - 4037-579 (8mm) | ||

| G | UNDER LICKER-IN 2nd Knife | SANMIT - D - 4038-512 (5mm) | ||

| D-K803(3 Flat C-System) D-K903 (Twin Flat System) | ||||

| A | FRONT-TOP KNIFE | SANMIT - D - 4039-495 | ||

| B | FRONT-BOTTOM KNIFE | SANMIT - D - 4040-495 | ||

| C | BACK-TOP KNIFE | SANMIT - D - 4041-494 | ||

| D | UNDER LICKER-IN 1st Knife | SANMIT - D - 4042-536 (9mm) | ||

| E | UNDER LICKER-IN 2nd Knife | SANMIT - D - 4043-671 (6mm) | ||

| F | UNDER LICKER-IN 3rd Knife | SANMIT - D - 4044-671 (6mm) | ||

| D-K800 | ||||

| A | STRIPPING FILLET KNIFE | SANMIT - D - 4045-996 | ||

| T-C03 / 05 / 5-3 / 06 /08 | ||||

| A | FRONT-TOP KNIFE | SANMIT - D - 4046-538 | ||

| B | FRONT-BOTTOM KNIFE | SANMIT - D - 4047-538 | ||

| C | BACK-SUCTION-TOP KNIFE | SANMIT - D - 4048-725 | ||

| D | BACK-TOP KNIFE | SANMIT - D - 4049-538 | ||

| E | UNDER LICKER-IN | SANMIT - D - 4050-450 | ||

| F | UNDER LICKER-IN - for TC5 Only | SANMIT - D - 4051-1006 | ||

| T-C11 | ||||

| A | C-SYSTEM-SUCTION HOOD KNIFE | SANMIT - D - 4052-578 | ||

| T-C360 | ||||

| A | UNDER LICKER-IN KNIFE | SANMIT - D - 4053-578 | ||

| C50 & C51 | ||||

| A | FRONT-TOP KNIFE | SANMIT - D - 4054-619 | ||

| B | FRONT-BOTTOM KNIFE | SANMIT - D - 4055-619 | ||

| C | BACK-TOP KNIFE | SANMIT - D - 4056-619 | ||

| D | UNDER LICKER-IN 1st Knife | SANMIT - D - 4057-620 (10 mm) | ||

| E | UNDER LICKER-IN 2nd Knife | SANMIT - D - 4058-620 (10mm) | ||

| C4 | ||||

| A | FRONT-ECC KNIFE | SANMIT - D - 4059-672 | ||

| B | FRONT-ICC KNIFE | SANMIT - D - 4060-673 | ||

| C | BACK-ECC KNIFE | SANMIT - D - 4061-672 | ||

| D | BACK-ICC KNIFE | SANMIT - D - 4062-673 | ||

| E | UNDER LICKER-IN 1st Knife | SANMIT - D - 4063-576 (8mm) | ||

| F | UNDER LICKER-IN 2nd Knife | SANMIT - D - 4064-576 (8mm) | ||

| MK4 | ||||

| A | UNDER LICKER-IN KNIFE | SANMIT - D - 4065-264 | ||

| MK5 & MK6 | ||||

| A | FRONT- KNIFE | SANMIT - D - 4066-780 | ||

| B | BACK- KNIFE | SANMIT - D - 4067-780 | ||

| C | UNDER LICKER-IN TRASH - KNIFE | SANMIT - D - 4068-496 (6mm) | ||

| D | UNDER LICKER-IN | SANMIT - D - 4069-455 (10mm) | ||

| HOWA | ||||

| A | UNDER LICKER-IN KNIFE | SANMIT - D - 4070-587 | ||

| CHINESE | ||||

| A | UNDER LICKER-IN KNIFE - FA221-D | SANMIT - D - 4071-628 | ||

| B | UNDER LICKER-IN KNIFE - FA225 | SANMIT - D - 4072-628 | ||

| WIRKBAU | ||||

| A | UNDER LICKER-IN 1st Knife | SANMIT - D - 4073-575 (12mm) | ||

| B | UNDER LICKER-IN 2nd Knife | SANMIT - D - 4074-574 (8mm) | ||

| MARZOLI CX300 | ||||

| A | UNDER LICKER-IN 1st Knife | SANMIT - D - 4075-776 | ||

| B | UNDER LICKER-IN 2nd Knife | SANMIT - D - 4076-776 | ||

| SANMIT C-SYSTEM KNIVES | ||||

| A | SM.3HA / V3 /V4 & C.1/2, C.1/3 | SANMIT - E- 5001-173 | ||

| B | D-K740, 760, 780, 800, 803 & 903 | SANMIT - E - 5002-102 | ||